Jewelry box packaging reflects how your brand is perceived by customers. A well-designed box makes your product appear more premium. It also makes a good impression on the customers. Paperboard jewelry is trendy for jewellery boxes due to its convenience and environmental friendliness. The market size can increase to $118.6 million from $87.4 million by 2034. Unbleached paperboard can be the champion with a sales proportion of 67.30%. Increasingly, consumers seek eco-friendly options, and therefore paperboard on jewelry is perfect for a mix of style and passion for the earth.

The Role of Paperboard in Jewelry Packaging

Customization and Branding Opportunities

Unique designs for brand identity

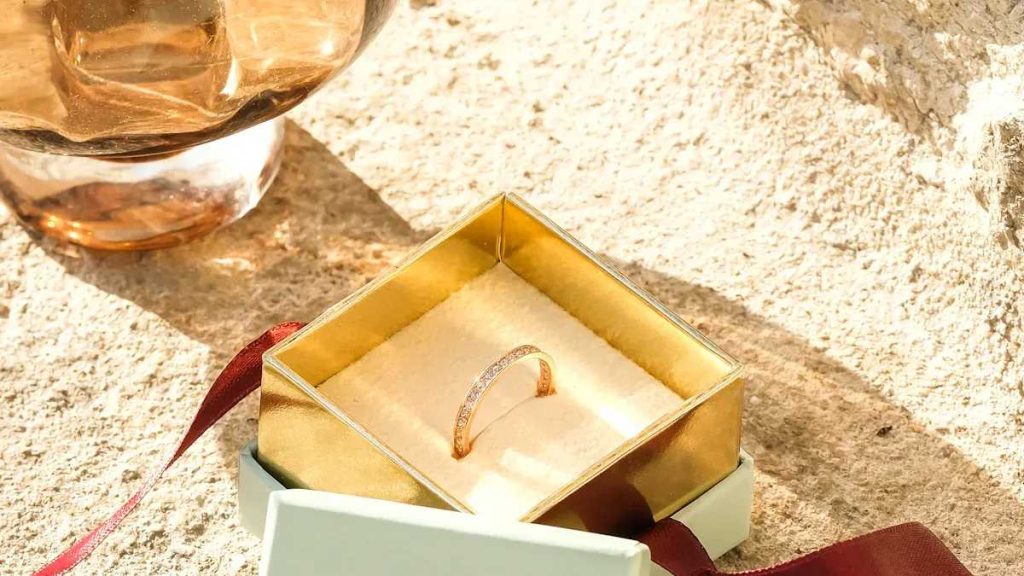

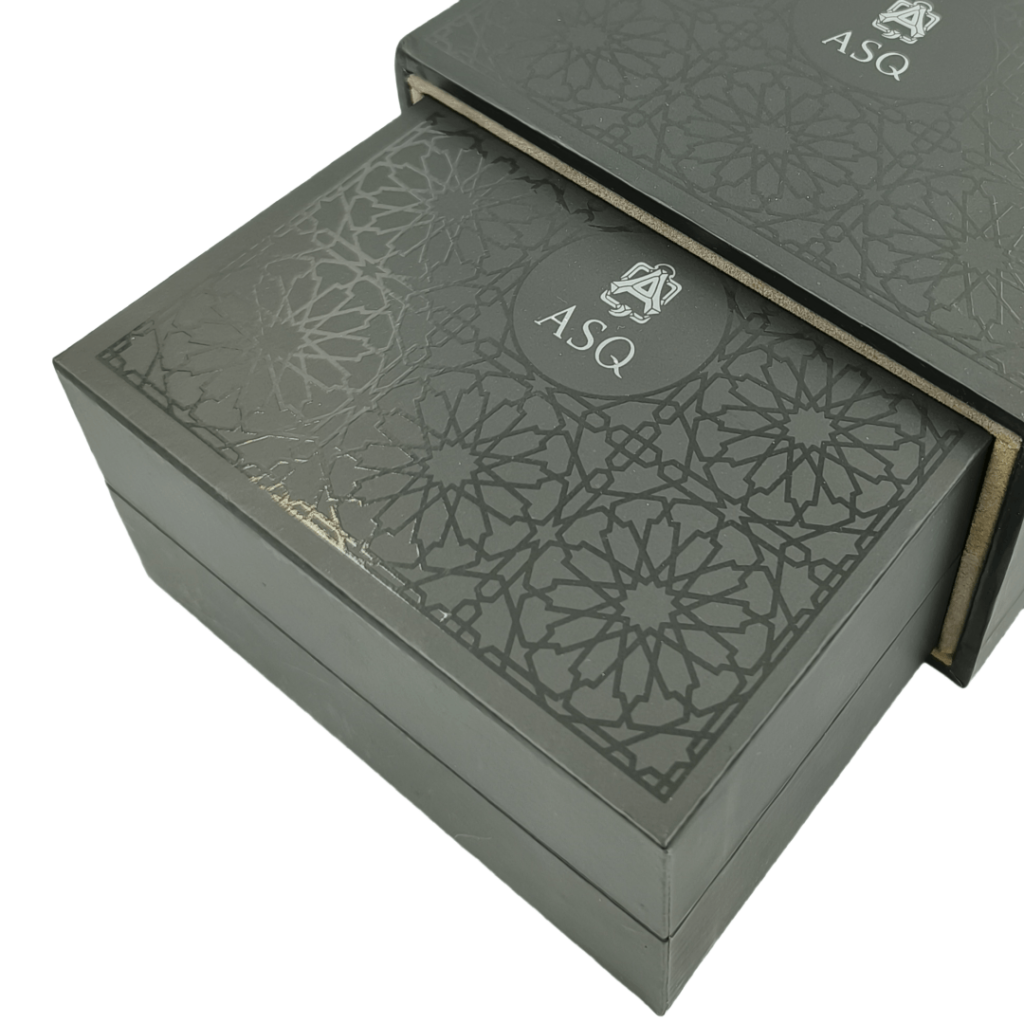

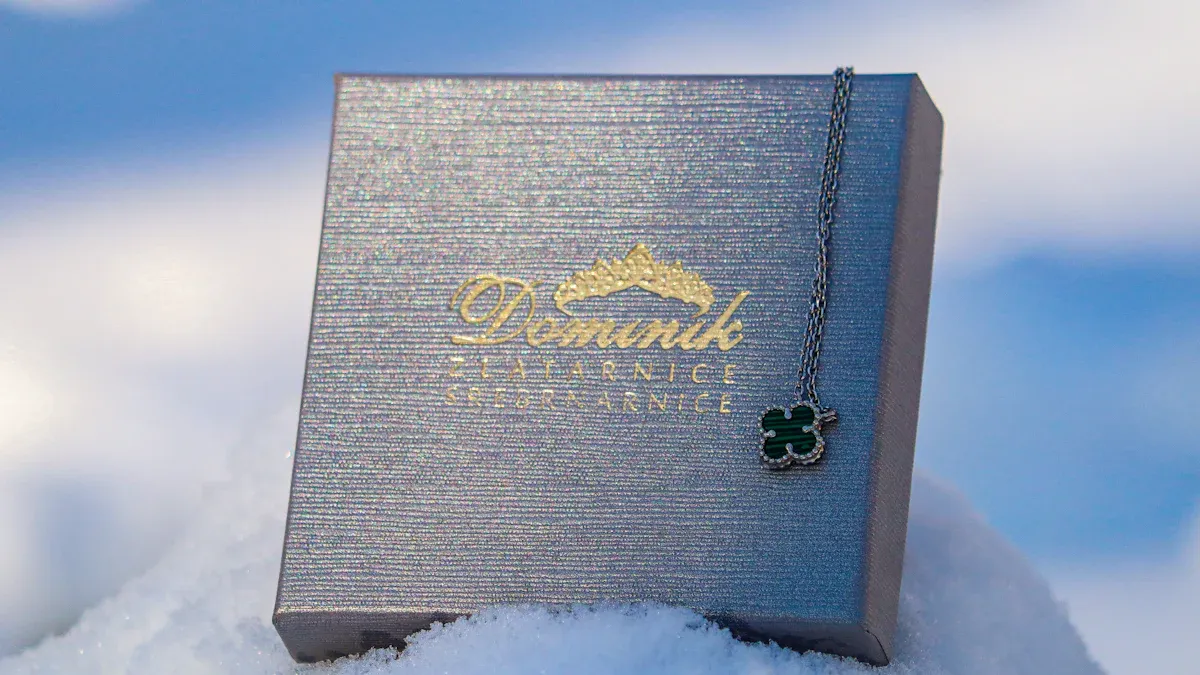

Paperboard is how you design your brand’s packaging. You can make the box whatever size, shape, and finish you’d like. That is to say that you can design packaging that resonates with customers. Tiffany & Co.’s blue box communicates luxury and love to customers. Cartier communicates in distinctive texture and hidden crevices to deliver quality and uniqueness to customers. These prints do make your brand more engaging and memorable.

Paperboard is ideal for full-color printing, logo, and pattern. Embossing and foil stamping add style and sophisticated look for your box. Paperboard enables you to make your packaging functional as a strong branding tool.

Flexible shapes, sizes, and finishes

Paperboard is simple to form any shape for any jewelry size. Ring covers or bigger for necklaces can be simply made. Paperboard weighs little, and shipping will be cheaper, which is ideal for e-shops. Paperboard is applied for finishings like gloss or touch varnishes. These types of treatments will keep the box clean and respectable as well as protect the box from scratching.

Brands such as Bulgari employ strong forms and vibrant colors for their paperboard packaging. They are conspicuous and easy to spot due to that. As paperboard is also flexible, you can design great things in a competitive market.

Enhancing Presentation and Value

Simple and stylish designs

Simple paperboard designs are popular as they bring the product to scale. One or double color with detailed features is clean as a finish. Embossed logo boxes are good when the color of the box is white. Plain outside and inside patterning is what Elly Jewelry uses in a bid to surprise and stun customers.

Simple designs are what suit the prevailing green themes. Paperboard is recyclable and therefore green. By utilizing simple designs, you can create the value feel and get green buyers.

Fancy textures and colors for a luxury feel

The feel of paperboard packaging affects how customers see your brand. Textures like embossing, soft finishes, and velvet coatings add soft touch provide a luxury touch. These properties provide an opening thrill touch and identify customers with your brand. For example, Bulgari uses textured paper and bold color to provide luxury and innovation.

Delicate textures not just look wonderful but also cause your jewelry to look more expensive. Smooth designs are easy to understand and enable clients to make decisions faster. Incorporating textures to your packaging renders it unique and shows that your company is invested in quality products.

From Paperboard Sheet to Finished Jewelry Box

Understanding Paperboard Properties

Thickness and Weight Considerations

Paperboard thickness and weight play a significant role in jewelry box packaging. The higher the paperboard thickness, the greater protection for fragile items like necklaces and rings. It will make the box more robust during transit and handling. However, being too thick will be more expensive and contribute to box weight. This may mean higher shipping charges.

Light paperboard is appropriate for miniatures, especially web merchandising. It remains affordable in postage cost and still remains effective in guarding commodities. Getting the appropriate ratio of weight to thickness renders packaging worthwhile and cost-efficient.

Strength and Durability Features

Hard paperboard offers a protective cover for jewelry while in transit. A quality paperboard is compressible and puncture-resistant. The fibers’ strength depends on utilized fibers. It is stretchable due to softwood fibers and sturdy because of hardwood fibers.

Adding laminations or coating extends the life of the paperboard. It waterproofs the box and will not be easily damaged, making it ideal for long-term use. Strong paperboard indicates that your business values quality.

Manufacturing Process Overview

Printing Techniques for Branding

Printing turns plain paperboard into eye-catching packaging. Offset printing creates sharp images and bright colors for fancy boxes. Digital printing is great for small orders and custom designs.

- Offset Printing: Offset litho is mass commercial printing by which the ink is displaced from a metal plate to a rubber blanket and from it onto the paperboard surface. Offset litho is most prevalent high-volume, high-quality printing.

- Digital Printing: It prints directly from digital files onto the paperboard similar to a large office inkjet or laser printer but on enormous industrial scale. It does not need print plates.

- Hybrid Approach: The alternative and maybe better solution is to take advantage of the best of both: digital printing to create prototypes, specialty or small print runs, or test market, and backup with offset for mass reproduction runs. This solution can give a balance of speed, flexibility, cost savings, and quality.

Die-Cutting for Box Shapes

Die-cutting is a precise production readiness with crisp pre-cut steel rule dies to punch cut the paperboard sheets into flat rigid blanks or shapes. Blanks are flat cut-outs of the box before folding. Cutting has to punch cut detailed designs, windows, tabs, slots, and other functional details required for assembling and use of the box.

Crease folds and sharp edges are made by die-cutting. Experiment with new shapes to make your packs that special something. Die-cutting is the most important process in making paperboard convert to stylish jewelry boxes.

Creasing and Scoring

Creasing and scoring are pre-process activities that make paperboard folding neat and accurate. Creasing is folding the board over along a definite line into a localized distortion area as a hinge. The deformity is contained, relaxing the board along the crease line so it folds without cracking or unattractive bulging on the outside surface. Scoring, too, places a linear mark or groove in the board to guide the fold. To ensure quality output, especially heavy paperboards, creasing precedes folding.

Structural Design Elements

Rigid vs. Folding Boxes

Rigid boxes feel fancy and protect items well. They don’t collapse and often have decorative paper for a nice look. Folding boxes are lighter and cheaper. They ship flat and are easy to put together.

Use rigid boxes for expensive jewelry and folding boxes for everyday items. Both types can be customized to match your brand.

Internal Compartments and Dividers

Compartments are clean and jewel-friendly. Dividers keep items from tangling or scratching. There is additional padding with foam inserts, and luxurious touch for those boxes with velvet interiors.

These advantages enhance unboxing and also protect your jewelry. Interior design focus ensures that your company pays attention to details and quality.

Finishing Touches for Aesthetics

Lamination Options for Protection

Lamination is a finishing operation whereby a thin plastic sheet (most commonly polypropylene, polyester, or nylon) is bonded over the printed paperboard surface by the action of an adhesive, usually heat and/or pressure-activated. Lamination does a number of things: it really beautifies the appearance of the package by allowing high gloss or smooth matte finishes; it adds strength to the paperboard with added tear strength, scuff resistance, moisture resistance, and fingerprint resistance; it guards against rubbing off or wear of the print beneath; and can add special tactile characteristics, which add to the perceived value of the jewelry box.

You can pick from different lamination types based on your brand:

- Gloss Lamination: Makes the surface shiny and colors brighter.

- Matte Lamination: Gives a smooth, non-shiny look for a classy style.

- Soft-Touch Lamination: Adds a soft, velvet-like feel for a luxury touch.

Proper lamination can cause your packaging to dazzle while not sacrificing its function and strength.

Specialty Coating for Luxury Appeal

Specialty coatings turn plain packaging cool. Specialty coatings are used to apply distinctive textures and finishes that attract attention. For example, specialty finishing on linings not only deliver jewelry but also upgrade the unboxing experience.

Popular specialty coatings include:

- Foil Stamping (Hot Stamping): Application of metallic (gold, silver, copper) or colored foil on specific areas of the paperboard surface using heat and pressure in a hot die. Foil stamping leaves a shiny, reflective metallic sheen or opaque color on such as logos, copy, borders, or delicate design and instills luxury and quality simultaneously.

- Embossing/Debossing: Both of these effects create a three-dimensional look on the surface of the paperboard. Embossing makes the individual design features (i.e., logos, patterns, lettering) raised above the surface, while debossing makes them press below the surface. Both create texture, depth, and upper-class-feeling tactile look that assists in creating the high-end look of the package.

- Spot UV Coating (Spot Varnish): Varnish specific areas of the image with a clear high-gloss UV-cured varnish, usually over a matte laminated surface. Extremely high contrast between coated glossy highlight and matte substrate produces strong visual impact and focuses viewer’s eye on the specific areas like logos or graphics. Spot UV further deepens colors and provides an additional protective coat for treated surface.

- Specialty Coatings (e.g., Aqueous (AQ) Coating, Pearlescent Coatings): Aqueous coatings are waterborne liquid or thin paint-like consistency coatings which can be flood coated to the whole world, or spot coated to a part of an area, to create scuffing resistance and fingerprint resistance and obtain very subtle sheen, satin, or flat gloss looks. They have more ecological value than some solvents-based varnishes. AQ coating is also could be on offer, together with offset print, as an option. Pearlescent or effect finishes are also being used, giving the paint special visual properties.

These details make your jewelry packaging match your brand’s high-end image and leave a strong impression on buyers.

Overview of Printing and Finishing Techniques for Paperboard Jewelry Boxes:

| Technique | Brief Description of Process | Key Aesthetic/Functional Impact | Typical Suitability for Jewelry Box Types/Segments | Interdependencies/Considerations |

| Offset Printing | Ink transferred from plates to blanket to paperboard. | High color fidelity (Pantone), sharp details, excellent for large volumes. | High-volume luxury and premium boxes, intricate designs. | Higher setup cost, less economical for small runs. Best for consistent quality. |

| Digital Printing | Inkjet or laser printing directly from digital files. | Variable data capable, cost-effective for small runs, quick turnaround. | Small runs, personalized/custom boxes, prototypes. | Per-unit cost higher for large volumes, Pantone matching can be approximate. |

| Foil Stamping | Heat and pressure transfer metallic/pigmented foil to surface. | Adds metallic sheen, luxury appeal, highlights key elements. | Premium and luxury branding, logos, accents. | Requires a die, adds cost/time. Paperboard surface and ink compatibility important. |

| Embossing | Creates a raised design on the paperboard using a die and counter-die. | Adds tactile dimension, sophisticated texture, premium feel. | Luxury packaging, logos, patterns. | Paperboard needs sufficient strength/flexibility. Adds cost/time. |

| Debossing | Creates a recessed design on the paperboard using a die and counter-die. | Subtle texture, understated elegance. | Premium and minimalist designs. | Similar considerations to embossing. |

| Matte Lamination | Bonding a non-reflective plastic film to the paperboard. | Smooth, elegant, non-glossy finish, soft feel, reduces glare. | Luxury and premium boxes, sophisticated branding. | Can slightly mute vibrant colors. Good for hiding fingerprints. |

| Gloss Lamination | Bonding a shiny plastic film to the paperboard. | High-shine, vibrant finish, enhances color pop, provides good scuff protection. | Mid-range to premium boxes, designs needing high impact. | Can show fingerprints and scuffs more easily. |

| Soft-Touch Lamination | Bonding a matte film with a unique velvety/rubbery texture. | Luxurious, exceptionally soft tactile feel, premium matte appearance. | High-end luxury packaging, items where tactile experience is key. | More expensive than standard laminations. |

| Spot UV Coating | Applying a high-gloss UV varnish to specific areas of the design. | Creates contrast with matte surfaces, highlights elements, adds depth and shine selectively. | Premium packaging, often used on logos or graphics over matte lamination. | Requires precise registration. Best on coated or laminated surfaces. |

Quality Control Measures

Testing for Structural Integrity

Packaging is the key to protecting jewelry from shock. High-quality paperboard will defen buckle or blow apart, and will keep contents in transit safe. Quality control has strict testing for abuse resistance in boxes.

Key tests include:

- Compression Testing: Checks if the box can handle pressure without breaking.

- Drop Testing: Makes sure the box stays safe after being dropped.

- Moisture Resistance Testing: Tests if the box holds up in wet conditions.

These tests ensure your packaging is strong and shows your brand cares about quality.

Ensuring Print Quality Standards

Good print brings your brand design to life. High quality for sharp logos and rich colors must be present. A very high quality system makes every batch look perfect.

| Quality Control Metric | Description |

|---|---|

| Quality Assurance | Careful checks make sure every detail is correct. |

| Quality Management System (QMS) | A good QMS helps keep quality a top priority. |

| Monitoring and Measurement | Tools and checks keep print quality consistent. |

| Regulatory Compliance | Packaging follows customer needs and legal rules. |

| Improvement and Growth | Feedback and audits help make things better over time. |

| Traceability and Accountability | Records track quality and ensure high standards are met. |

By following these steps, you can create packaging that protects jewelry and boosts your brand’s image.

Sustainability Benefits of Paperboard in Jewelry

Eco-Friendly Material Properties

Recyclability and biodegradability

Paperboard is not the same as other products as it may be recycled dozens of times. Paperboard conserves resources and is not a producer of material waste. In contrast to plastic whose lifetime in the environment is hundreds of years, paperboard deteriorates under nature’s conditions. Paperboard does not ever contaminate nature and restores nature’s ecosystems back to their initial conditions. Paperboard, because it is constituted from natural ingredients, can be degraded into nonharmful components. This is what scores best for eco-friendly brands.

Tip: Picking recyclable and biodegradable packaging supports the environment and appeals to buyers who care about sustainability.

| Indicator | Description |

|---|---|

| Recyclability | Paperboard can be reused many times, saving energy and resources. |

| Biodegradability | It breaks down naturally, lowering pollution compared to plastic. |

| Renewable Raw Materials | Made from wood fibers that are harvested responsibly. |

| Circular Economy Contributions | Helps reduce landfill waste by being reusable and eco-friendly. |

Research shows paperboard is greener. Recycled paperboard creates less carbon dioxide than virgin content. It is thus an economic and environmentally friendly choice for jewelry packaging.

Use of FSC-certified and unbleached materials

Paperboard is made up mainly of FSC-certified wood, which comes from sustainably managed forests. The certifications ensure that trees are cultivated and harvested in a manner that does not disrupt animals and plants. Unbleached paperboard is even superior since it uses no toxic chemicals, and nature remains entirely untouched.

Certifications like ISO 14001 and FSC prove a focus on protecting nature. Here’s a quick look:

| Certification | Description |

|---|---|

| ISO 9001 | Ensures products meet high-quality standards. |

| ISO 14001 | Focuses on managing environmental impacts. |

| ISO 45001 | Promotes safe and healthy workplaces. |

| FSC | Guarantees responsible forest management. |

| PEFC | Supports sustainable forestry practices. |

Using the use of FSC-certified and unbleached paperboard sends a message that your business wants the world taken care of when packaging is at its best.

Supporting Environmental Goals

Lower carbon footprint compared to alternatives

Paperboard packaging also has a lower greenhouse gas emission compared to plastic or metal. Greenhouse gas is always minimized every time recycled fibers are applied in the production of paperboard. Carbon dioxide emitted at emission has been proved by scientists to be minimized more in recycled paperboard than in manufacturing virgin material.

For example, Tetra Pak cartons, made mostly of paperboard, lower their carbon footprint by 33%. That is, paperboard can be put to use while combating climate change.

Note: Choosing paperboard packaging helps your brand support global climate goals.

Contribution to circular economy practices

Paperboard keeps them in the loop for a longer period. Paperboard is reusable and recyclable, and it consumes and wastes less of it. Paperboard usage is forward in the system paradigm where the material is redesigned and not wasted.

Researches point out to us that paperboard is a step towards circular economy. They weigh its impact on carbon footprint, water consumption, and waste in order to ascertain that it is even more environmentally friendly.

Unbleached FSC paperboard is one of them. It presents sustainable sourcing without their existence of harmful chemicals in them. All these types are what the green consumers prefer, and paperboard is a very appropriate choice for jewelry packaging.

Market Trends in Paperboard Jewelry Packaging

Demand for Compact and Lightweight Designs

Popularity in e-commerce and shipping

E-commerce has changed the game of packaging design. Small and lightening designs are more than ever in the past a necessity. They save shipping expenses and keep goods safe from transit damage. Paperboard packaging is strong but not heavy. It can even be folded flat and warehoused and shipped without issues.

- The paperboard packaging market can grow from $381.4 billion in 2024 to $620.6 billion by 2034, with a 5.1% yearly growth rate.

- Packaging used in retail and e-commerce can grow by 7.9% every year between 2025 and 2034 because of protective packaging needs.

- People are increasingly environmentally conscious, and plastic prohibitions are forcing companies to shift away from plastic towards paperboard.

Online vendors like paperboard value it since it is light and inexpensive to send. It is also durable enough to hold jewelry and therefore make clients contented. This shows how green and smart packaging plays a crucial role in online selling.

Small-sized packaging for modern jewelry

Modern jewelry is small and stylish, such as the miniature earring or ring. They need small, secure boxes that are also adorable. Paperboard is great for making compact boxes that fit these items perfectly. It can also be shaped to secure the jewelry in a fashionable manner.

They consume less material, which is eco-friendly. This kind of environmental policy is attractive to green customers. Paperboard is a good option for businesses selling fashionable jewelry.

Regional and Cultural Influences

Customization for diverse markets

Locations have their own preferences. Some locations prefer bold colors and elaborate prints, while others prefer simple and elegant ones. Paperboard can easily be made to suit these preferences. You can place bold prints, embossed logos, or local designs that are attractive to local buyers.

For example, golden and red color packaging in Asian countries is trendy as it reflects prosperity and wealth. Western countries favor simple designs and light colors. When you can incorporate local fashion into your packaging, you are able to identify with your clients.

Incorporating cultural motifs and sustainable values

Adding cultural patterns provides a personalized and distinctive appearance to the packaging. Paperboard may be printed with familiar patterns, motifs, or even text. This creates the packaging appear exceptionally lovely and even more related to customers.

It is essential to preserve the world even today. Customers look for environmentally friendly products, and paperboard is among them. Requesting materials such as FSC-certified or unbleached paperboard demonstrates that your company values the environment. Combining cultural heritage with green practices sets your company apart in a competitive business environment.

Challenges and Innovations in Paperboard Jewelry Packaging

Solving Durability Issues

Making paperboard stronger for fragile jewelry

It truly is important to care for fragile jewelry when shipping. Packaging needs to be safe but appealing. Jewelry boxes protect items from damage and keep them in mint condition. Layered paperboard or paperboard offers fragile items such as necklaces or rings the durability they need.

Including bamboo in packaging makes it more durable. Bamboo is green and environmentally friendly too. Its natural look also makes your company stand out. Harvesting bamboo sustainably, for example, via FSC certification, provides your packaging with an eco-friendly edge.

Custom features also provide protection. Velvet lining, foam inserts, and safety zones protect jewelry. These comforts make your packaging personal so that it carries your signature and gives customers an excellent unboxing experience.

Coatings and linings for extra protection

Protective coatings make paperboard last. Anti-abrasion tops or soft touch laminating maintains the surface in like-new condition without abrasion. Water repellent coatings and seal the package during transportation.

Lining with internal linings like velvet and satin gives extra cushioning. Besides the jewelry protection, they also give a high-end finishing to the package. Coatings and linings with you, you create strong and fashion-packaging that indicates you care for quality.

Managing Costs and Quality

Budget-friendly options for brands

Finding the right balance between cost and quality is key. You achieve that by controlling material cost, manufacturing process and shipping charges. Shipping in paperboard light is not costly but possesses some strength. That is ideal for the online shopper.

Green without compromising on quality exists with new materials today. Green and cheap is recycled paperboard. Saving on money by using the right material and going green.

New manufacturing methods

Technological improvements have greatly improved the manufacturing of paperboard packaging. Automated cutting and digital printing allow you to save more resources and minimize waste. The process is economical in the long term and improves quality.

Sustainability is also on our agenda. Green processes are the manner in which we carry out activities currently, the manner in which we want the customer to feel. Green processes enable you to produce cost-effective, quality, sustainable packaging.

Tip: Using advanced manufacturing methods improves your packaging and shows your brand cares about innovation and the planet.

Paperboard jewelry packaging is stylish and eco-friendly. They reduce packaging waste by 28% and increase customer satisfaction by 19%. Unconventional designs like seed-filled paper or hand-drawn slide box are perfect. Custom drawer boxes led to sales increased by 140% for Etsy merchants. This box enhances your business reputation and saves huge amount per year on postage. Using paperboard shows you are green and in front of the pack in a saturated marketplace.

Frequently Asked Questions (FAQs)

Q: Why is paperboard good for jewelry packaging?

A: Paperboard is strong, light, and eco-friendly. Its smooth surface works well for printing, making it great for branding. You can add finishes, textures, and coatings to make it look fancy.

Q: Can paperboard keep delicate jewelry safe?

A: Yes, paperboard can protect fragile jewelry. Foam inserts, dividers, and velvet linings keep items secure. These features stop scratches and damage during shipping.

Q: How can paperboard be customized for branding?

A: Paperboard is easy to customize. You can pick different shapes, sizes, and finishes. Techniques like embossing, foil stamping, and spot UV coating make your packaging unique and match your brand.

Q: Is paperboard packaging good for the environment?

A: Yes! Paperboard can be recycled and breaks down naturally. It’s often made from renewable materials. Using FSC-certified or unbleached paperboard makes it even better for the planet.

Q: What kinds of jewelry fit in paperboard packaging?

A: Paperboard works for all jewelry types, like rings, earrings, necklaces, and bracelets. It can be shaped into small boxes or larger ones with compartments for multiple pieces.

Q: How does paperboard compare to plastic or wood?

A: Paperboard is lighter, cheaper, and better for the planet than plastic or wood. It looks fancy with the right finishes. Unlike plastic, it breaks down naturally, and unlike wood, it’s easier to ship and customize.

Q: Can paperboard handle shipping to other countries?

A: Yes, paperboard is strong enough for long-distance shipping. Adding coatings and padding inside keeps jewelry safe during travel.

Q: What are popular finishes for paperboard jewelry boxes?

A: Popular finishes include matte lamination for a smooth look, soft-touch lamination for a velvet feel, and gloss lamination for bright colors. Spot UV and embossing add texture and make packaging look high-end.