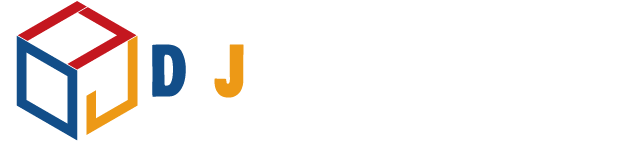

Set-up boxes, also known as rigid boxes, are high-end packaging solutions commonly used for luxury products, such as jewelry, watches, and high-end consumer electronics. These boxes are made from sturdy materials and are designed to protect the products inside from damage during shipping and handling. In this article, we will take a closer look at the different materials used to make set-up boxes and how they impact the design and functionality of these boxes.

Materials Used in Set-up boxes

The materials used to make set-up boxes can range from paperboard to plastic, with each material offering its own benefits and limitations. Let’s take a closer look at some of the most commonly used materials in manufacturing set-up boxes.

1. Paperboard

The paperboard we commonly use in production is grey board, one of the most popular materials used to make set-up boxes, and for obvious reasons. It is lightweight, affordable, and can be easily printed on, making it a suitable choice for custom branding. In addition, paperboard is a sustainable material, made from renewable resources and biodegradable.

However, paperboard is less durable than other materials and more prone to tearing and crushing. As a result, it is typically used for lighter products and for packaging that does not require a high level of protection. Alternatively, you can use high-grammage paperboard and laminate it with special paper, so its performance can be dramatically improved.

2. Chipboard

Chipboard is made from wood fibers from sawdust and other wood by-products. The fibers are then combined with resin or glue and pressed into sheets to create a dense and durable material. Chipboard is often used as a substitute for solid wood, as it is a more eco-friendly and cost-effective alternative. Chipboard is also more resistant to crushing, making it a wise choice for products that need extra protection during shipping and handling.

However, chipboard can be more difficult to print on, as it is not as smooth as paperboard. It can also be more expensive than paperboard, making it less accessible for budget-conscious businesses. In addition, you need to pay attention to the fact that poor-quality chipboard often has the problem of excessive formaldehyde, which has an impact on the health of consumers. So if you want to choose chipboard as a packaging material, please conduct adequate testing of the raw materials.

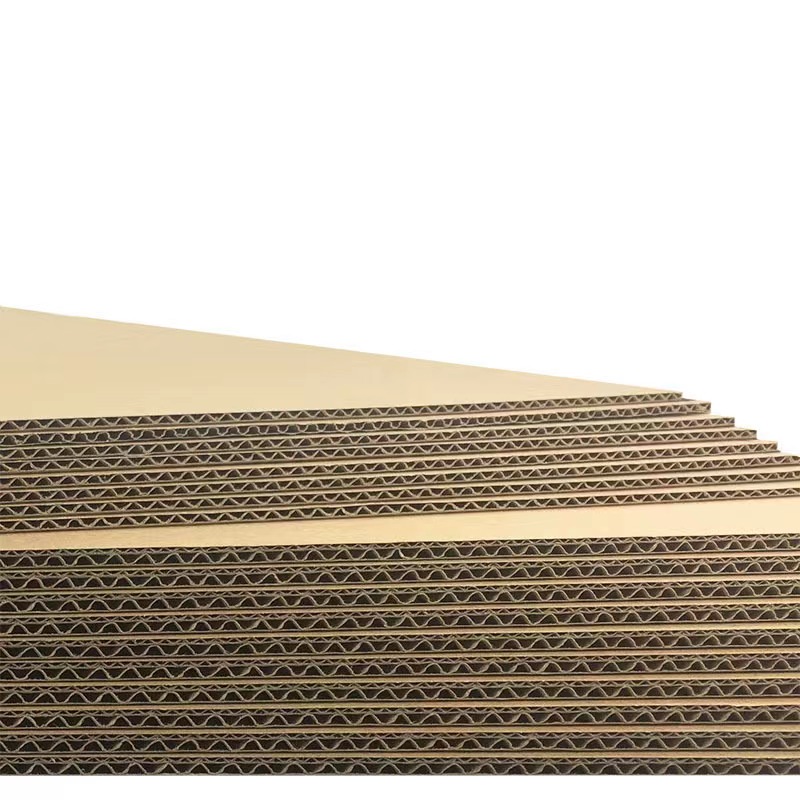

3. Corrugated board

Corrugated cardboard is a popular packaging material often used for shipping boxes. It is made by gluing together multiple layers of paperboard and adding a corrugated layer in between to provide extra strength. This material is lightweight, affordable, and protects against crushing and impact.

However, corrugated cardboard can be difficult to print on. Because of its corrugated structure, its surface has a kind of wave effect. Printing is not as flat and exquisite as paperboard. Therefore, relatively speaking, corrugated board is rarely used in set-up boxes.

4. Plastic

Plastic is another popular material for set-up boxes, and it offers a number of advantages over other materials. Plastic is waterproof, making it a practical choice for products that need to be protected from moisture. It is also lightweight, making it easy to transport and resistant to crushing, rendering it an ideal choice for products that need extra protection.

However, plastic can be more expensive than other materials and is not as eco-friendly. It is also more difficult to recycle than paperboard and chipboard, which makes it a less popular choice for environmentally conscious businesses.

Design considerations for set-up boxes

When designing set-up boxes, there are several important factors to consider, including the box size, the materials used, and the printing options. Let’s take a closer look at each design consideration in more detail.

1. Size

The size of the set-up box is an important consideration, as it will determine how much space is available for the product inside. The box size should be carefully chosen to ensure that the product fits snugly inside, without any movement or wiggle room. This will help to prevent damage to the product during shipping and handling.

2. Materials

As mentioned previously, the material used for the set-up box can impact its durability, eco-friendliness, and overall appearance. The material should be chosen based on the weight and type of product that will be packaged, as well as any specific requirements for protection or branding.

3. Printing options

Printing options for set-up boxes can range from simple logos and text to full-color graphics and images. Printing options should be chosen based on the desired look and feel of the packaging, as well as the specific branding requirements of the product. High-quality printing options can add a professional touch to the packaging, while also helping to promote the product and brand. In addition to conventional graphic printing, some effects are also important, such as embossing & debossing, foil stamping, UV coating, etc. These special effects can significantly enhance the texture of the packaging and highlight the brand tone.

In conclusion, set-up boxes are a versatile and effective packaging solution that can be tailored to meet the specific needs of a wide range of products. Whether paperboard, chipboard, corrugated board, or plastic, there is a material that is well-suited to every product and application. Businesses can create custom set-up boxes that effectively protect and promote their products by considering factors such as size, materials, and printing options.